See for yourself from our counting scales reviews.Ĭounting scales or parts counting scales can be incorporated into inventory management systems to increase process reliability and productivity. The information from an electronic counting scale or piece counting scale can help reduce production costs. Counting scales typically are used in many industries, including the manufacturing and distribution of automotive parts, electronics, and plastic or metal components. Sampling methods, operator messages and automatic accuracy improvements are user configurable as well.

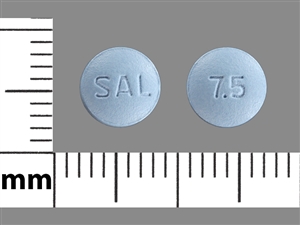

LAN 1313 PILL FULL

Some of the benefits of using a count scale include full barcode scanning and printing, a database configured to your specific needs, and full communication to your inventory/logistics planning and management systems. The electronic counting scale then subtracts the weight of the container from the overall weight of the goods.ĭiscover a full line of parts counting scales offering a wide range of benefits. An electronic counting scale can also take into account the tare weight, which is the weight of an empty container that may be holding the uniform parts. A strain gauge can be used to measure the amount of force that is exerted on an object. They do so digitally by using a component called a strain gauge. A count scale or piece counting scale can then compute the average piece weight. Industrial counting scales calculate the weight of a group of uniform items placed on platform scales. If parts are counted inaccurately, it can mean overfilling orders and therefore excessive costs, unstable production processes and a damaged reputation. Using a parts counting scale or count scale is a simple and fast way to determine the numbers of parts in receiving, warehousing, production or shipping, as you can see from the counting scales reviews for our industrial counting scales. In industrial environments, mistakes and inaccurate information can be costly.

0 kommentar(er)

0 kommentar(er)